What is Velvet?

Velvet is an opulent fabric that has enthralled fashion aficionados for generations. In this all-encompassing guide, we'll delve into the opulent past of velvet, tracing its roots from ancient epochs to contemporary vogues. We'll explore the intricate art of crafting velvet, dissect the manifold varieties of this sumptuous textile, and unravel the disparities among velvet, velveteen, and velour. Furthermore, we'll furnish you with fashion tips tailored for diverse occasions, proffer counsel on maintaining your velvet fabric, and dispel prevalent misconceptions surrounding this exquisite material.

The History of Velvet: From Ancient to Modern Trends

The illustrious chronicle of velvet can be retraced to bygone eras, where it was extolled for its plushness, extravagance, and lavish tactility. Initially forged from silk filaments, velvet symbolised affluence and prestige, gracing the attire of nobility and elites.

As time elapsed, velvet production proliferated worldwide, with technological strides yielding a panoply of velvet variants, encompassing cotton, rayon, and synthetic derivations. Presently, velvet remains an enduring icon, bedecking catwalks, gala soirées, and everyday ensembles with its resplendent allure.

How Velvet is Crafted?

The genesis of velvet entails a meticulous and labour-intensive process. It commences with the culling of superior fibres like silk, cotton, or synthetic amalgams which are subsequently spun into yarn. Employing specialised looms, the yarn is woven into a dense fabric, with dual layers interwoven concurrently to engender a dense pile. Post-weaving, the fabric undergoes a technique termed "cutting," where the yarn loops are sheared to yield the velvety softness emblematic of velvet. Lastly, the velvet is dyed, refined, and scrutinised for excellence before gracing the market.

Types of Velvet Fabric

Velvet fabric manifests in myriad incarnations, each distinguished by its singular texture, aesthetics, and utility:

Crushed Velvet

Characterised by its distinctive crumpled semblance, achieved through twisting or compressing the fabric, it exudes a luminous, textured veneer that refracts light beguilingly.

Panne Velvet

Exhibiting a flattened pile, it boasts a sleek, polished surface with a subdued lustre. Often favoured in drapery, upholstery, and evening ensembles, it exudes an aura of opulence.

Embossed Velvet

Adorned with intricate motifs or designs via heat stamps or rollers, it bestows texture and visual allure to the fabric, rendering it ideal for upholstery, decorative accents, and fashion embellishments.

Ciselé Velvet

Distinguished by its patterned exterior, crafted by excising some looped threads while retaining others, it yields a textured fabric with an elevated motif, infusing depth and dimension into the motif.

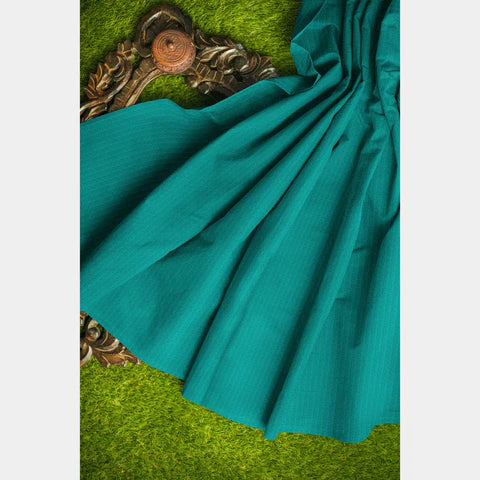

Plain Velvet

Commonly known as cotton velvet or velveteen, it constitutes the quintessential variant of velvet fabric. Boasting a compact pile and a smooth, homogeneous surface, it is versatile and suited to a myriad of applications.

Difference Between Velvet, Velveteen, and Velour Fabric

Though sharing congruences in texture and appearance, velvet, velveteen, and velour diverge in composition and construction:

Velvet

Traditionally derived from silk fibres, although now fashioned from cotton, rayon, or synthetic blends, it flaunts a dense pile with a plush texture, gracing formal attire, upholstery, and home accoutrements.

Velveteen

Akin to velvet in appearance, it comprises cotton fabric simulating the velvet aesthetic. Sporting a truncated pile, it exudes a semblance of opulence at a more budget-friendly price point.

Velour

A knitted fabric bedecked with a plush pile on one surface, it finds utility in sportswear, loungewear, and upholstery. Boasting a supple, cosy feel, it is prized for its robustness and softness.

Cloth Woven Fabrics

Weaving is the process of combining underpinning and weft factors to make a woven structure. The factors need neither be resemblant to each.

In weaving, lengthwise yarns are called underpinning; cornerwise yarns are called weft, or filling. Utmost woven fabrics are made with their external edges finished in a manner that avoids raveling; these are called selvages. They run lengthwise, resemblant to the underpinning yarns. The three drive weaves are straight, twill, and satin. Fancy weaves — similar to the pile, Jacquard, dobby, and leno — bear more complicated looms or special impend attachments for their construction.

Three types of weaves are straight, twill, and satin.

How the yarns are amalgamated determines the type of weave.

The yarn count and several foundations and filling yarns to the square inch determine the closeness or tautness of a weave. Woven fabrics may also be varied by the proportion of underpinning yarns to filling yarns. Some goods are achieved by the selection of yarns or combinations of yarns.

Straight Weaves

In the plain weave, each filling yarn passes over and under the underpinning yarns, with the order reversed in interspersing rows. Fabrics made in the plain weave include percale, muslin, and taffeta. Roasted goods in similar fabrics as faille and bengaline are produced by employing heavier yarns for either the underpinning or the stuffing. In the basket-weave, one or further stuffing yarns are passed alternatively over and under two or further underpinning yarns, as seen in monk’s cloth.

Twill Weaves

Twill weaves are made by interlacing the yarns in a manner producing slant caricatures, crests, or wales across the fabric. Wales may run from the upper right to the lower leftism of the fabric or the reverse. Twill fabrics include denim, gabardine, and blarney.

Satin Weaves

Satin weaves have a lustre produced by exposing further foundations than paddings on the right side of the fabric. The exposed foundations are called docks. In the sateen weave, the process is reversed, and the exposed paddings form the docks. The quantum of twist in the yarns and the length of the docks produce variations. Fabrics made in these weaves include slipper satin, satin waffle, and colourful sateen types.

Pile weaves produce fabrics with raised, thick shells. They can be made by weaving redundant underpinning yarns over cables, producing circles that are cut as the cables are withdrawn; by conforming impend pressure to produce circles that are constantly left uncut; by using redundant stuffing yarns to produce docks that are cut after weaving; or by weaving two cloths face to face, binding them together with a redundant set of foundations that form the pile when the fabrics are cut piecemeal. Exemplifications of woven pile fabrics include velvet, plush, terry cloth, and numerous synthetic furs.

Styling Tips for Velvet Fabric

Velvet fabric confers a touch of refinement and sophistication to any ensemble or interior milieu. Here are some styling directives for incorporating velvet into your sartorial and domestic domains:

Formal Affairs: Opt for a velvet blazer or gown for an opulent evening ensemble exuding timeless allure and sophistication.

Casual Outings: Pair a velvet top or dress with denim or leggings for a chic daytime ensemble, melding comfort and style seamlessly.

Home Decor: Infuse velvet throw pillows, drapes, or upholstery into your living space for an opulent accent that elevates the overall ambiance.

Accessories: Augment your ensemble with velvet scarves, purses, or footwear to inject texture and colour sans overpowering the look.

Layering: Experiment with layering velvet pieces—a velvet blazer over a silk blouse or a velvet skirt paired with a cashmere pullover—for an en vogue and stylish aesthetic.

How to Care for Your Velvet Fabric: Tips and Tricks

Prudent maintenance is necessary to preserve the allure and durability of velvet fabric. Here are some tips and tricks for nurturing your velvet garments and furnishings:

Dry Cleaning: Choose for dry cleaning to circumvent damage to the delicate fibres and uphold the plush texture and appearance.

Spot Treatment: For minor spills or blemishes, gently blot the afflicted area with a pristine, damp cloth and mild detergent, then air-dry.

Brushing: Routinely brush your velvet fabric with a tender-bristled brush to expunge dust, debris, and pet dander, reinstating its plushness.

Steam Cleansing: Employ a handheld steamer to delicately steam your velvet fabric, holding it aloof to avert moisture damage and revitalise its plush texture.

Sunlight Avoidance: Shelter velvet garments and furnishings from direct sunlight, as protracted exposure may induce fading and fibre degradation.

Conclusion

In conclusion, velvet fabric is a timeless classic that has stood the test of time, captivating fashion enthusiasts with its luxurious texture, rich history, and versatile appeal. Whether adorning formal attire, home furnishings, or everyday accessories, velvet adds a touch of elegance and sophistication to any setting. By understanding its origins, manufacturing process, and care techniques, you can enjoy the beauty of velvet fabric for generations to come.

Most Asked Question Related to Velvet Fabric

1. What is the history behind velvet fabric, and how has it evolved over time?

Ans: Velvet has a rich history dating back to ancient times when it was associated with royalty and nobility. Over time, technological advancements have led to the creation of various types of velvet fabric.

2. What are the different types of velvet fabric, and how do they differ from each other?

Ans: There are several types of velvet fabric, including crushed, panne, embossed, ciselé, and plain. These differ in texture, aesthetics, and utility.

3. What are some tips for incorporating velvet into fashion and home decor?

Ans: To incorporate velvet into your fashion or home decor, consider using it for clothing items, accessories, or decorative accents like pillows and drapes. Keep in mind that velvet can add an elegant and sophisticated touch to any setting.

4. How is velvet fabric made, and what is the process behind its creation?

Ans: Velvet fabric is created through a meticulous process that involves selecting superior fibres, spinning them into yarn, weaving the fabric on specialised looms, cutting the yarn loops to create a soft pile, and dyeing and refining the fabric before it's ready for use.

5. What are the best practices for caring for and maintaining velvet fabric?

Ans: To care for velvet fabric, it's recommended to opt for dry cleaning to preserve its delicate fibres and plush texture. For minor spills, gently blot the affected area with a damp cloth and mild detergent, then air dry.

Call Us

Call Us